Nouveau !

Découvrez notre partenariat avec Metalskin, la peinture antibactérienne révolutionnaire

Pôle Traitements de Surface

Traitement anticorrosion des surfaces métalliques

Certifications : ISO 9001 • IATF 16949 • EN 9100 • Sans Chrome 6

La force de notre Pôle

:

des traitements de surfaces complémentaires

Depuis plus de 50 ans, notre entreprise familiale s’impose comme l’un des acteurs majeurs du traitement anticorrosion des surfaces métalliques. Nos différentes techniques complémentaires permettent de lutter efficacement contre la corrosion des pièces métalliques, en leur conférant des propriétés mécaniques et en les rendant esthétiques.

La démarche de Lean Management, l’intégration et la propagation du savoir, la combinaison entre jeunesse et expérience… Autant d’atouts qui font également de notre entreprise une structure à dimension humaine.

RSE : nos engagements et exigences de qualité

Conscientes de leur responsabilité sociale et environnementale, nos quatre entreprises s'attachent à respecter l'environnement, tant naturel qu'humain, en s'inscrivant dans une démarche de développement durable.

Nos engagements ? Fournir un produit conforme aux attentes de nos clients livré à la date escomptée, tout en réduisant notre empreinte environnementale, en favorisant la production locale et en offrant des traitements à hautes performances.

La French Fab

En tant qu’acteur industriel dynamique et fort de notre esprit d’innovation permanent, notre entreprise s’associe au mouvement « La French Fab » et assume avec fierté son implantation française.

Notre entreprise incarne parfaitement les valeurs de ce mouvement et porte des ambitions profondes dans les domaines de l’environnement, de l’innovation industrielle et du bien-être des collaborateurs.

Des prestations nombreuses

pour des secteurs multiples

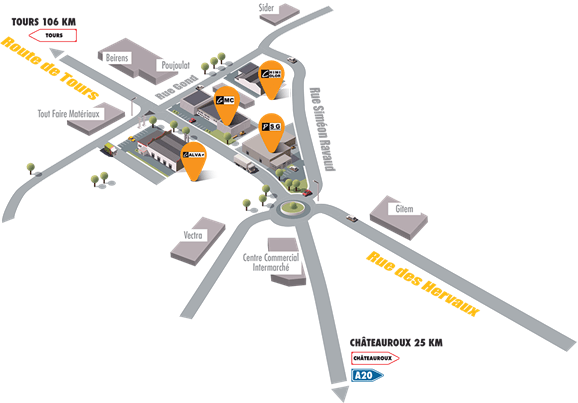

Nos quatre entreprises, situées sur le même site, proposent des traitements de surfaces à l'attention de huit grands types d'activité.

Aéronautique / Militaire

Automobile

Poids lourds

Ferroviaire

Cycles / Loisirs

Agricole

Bâtiment

Énergie

Aéronautique / Militaire

Automobile

Poids lourds

Ferroviaire

Cycles / Loisirs

Agricole

Bâtiment

Energie

Le secteur de l’aéronautique / militaire

Le Pôle Traitements de Surface est un partenaire privilégié pour l’ensemble des fabricants et sous-traitants des entreprises spécialisées dans les secteurs de l’aéronautique, de l’aérospatial et de l’armée. Notre entreprise investit régulièrement dans ce domaine afin de répondre aux exigences spécifiques dans ces secteurs d’activité.

Tous nos procédés sont parfaitement adaptés aux besoins des grands donneurs d’ordres et répondent aux exigences anticorrosion les plus strictes. Nous mettons également un point d’honneur à offrir des

solutions innovantes et respectueuses de l’environnement.

Le secteur du transport : automobile, ferroviaire…

Les contraintes liées à la protection des moyens de transport sont très variées et également très exigeantes. Les solutions de traitement techniques mises en œuvre doivent à la fois répondre aux problématiques de corrosion, d’usure et de résistance mécanique, et prendre en considération les préoccupations environnementales.

Le Pôle Traitements de Surface est votre interlocuteur de référence pour toute demande de

traitement anticorrosion concernant le secteur automobile. Notre expertise s’étend également aux secteurs des poids lourds, du ferroviaire et des cycles et loisirs.

Le secteur de l’industrie : bâtiment, énergie…

Le Pôle Traitements de Surface est également un interlocuteur de référence pour tous les industriels dans les secteurs de l’énergie et du bâtiment ainsi que dans le domaine agricole.

Le secteur de l’énergie, par sa spécificité et ses contraintes uniques, demande une expertise particulière et de haute qualité afin de répondre aux problématiques techniques et environnementales. Nos solutions anticorrosion sont parfaitement adaptées au secteur du nucléaire, de l’éolien ou encore du solaire.

Les secteurs agricoles et du bâtiment sont également concernés par le processus de corrosion. C’est pourquoi nous leur fournissons des services de traitement des surfaces métalliques, garantissant à chaque composant le respect des attentes en matière de performances.

L'énergie est notre avenir, économisons-la !

Tous droits réservés

Pôle Traitements de Surface